In many industrial environments, the tools you choose can be the difference between a safe operation and a catastrophic accident. A single spark in the wrong place—near flammable vapors, combustible dust, or explosive gases—can trigger fires or explosions that endanger lives and destroy facilities. That’s where non sparking tools become essential safety equipment.

At Sonta Tools, we understand that safety is non-negotiable. Our comprehensive selection of non-sparking tools protects workers in high-risk environments across the UAE and beyond. Here’s everything you need to know about these critical safety tools.

Why Standard Tools Create Dangerous Sparks

Standard tools are typically made from steel—a material that generates sparks when struck or rubbed against hard surfaces. In most environments, these tiny sparks pose no threat. But in areas where flammable materials are present, even the smallest spark can ignite a fire or cause an explosion.

Non-sparking tools eliminate this risk entirely. These specially designed tools are crafted from materials that minimize spark generation during use, providing a safer alternative for high-risk operations.

What Makes Non-Sparking Tools Different

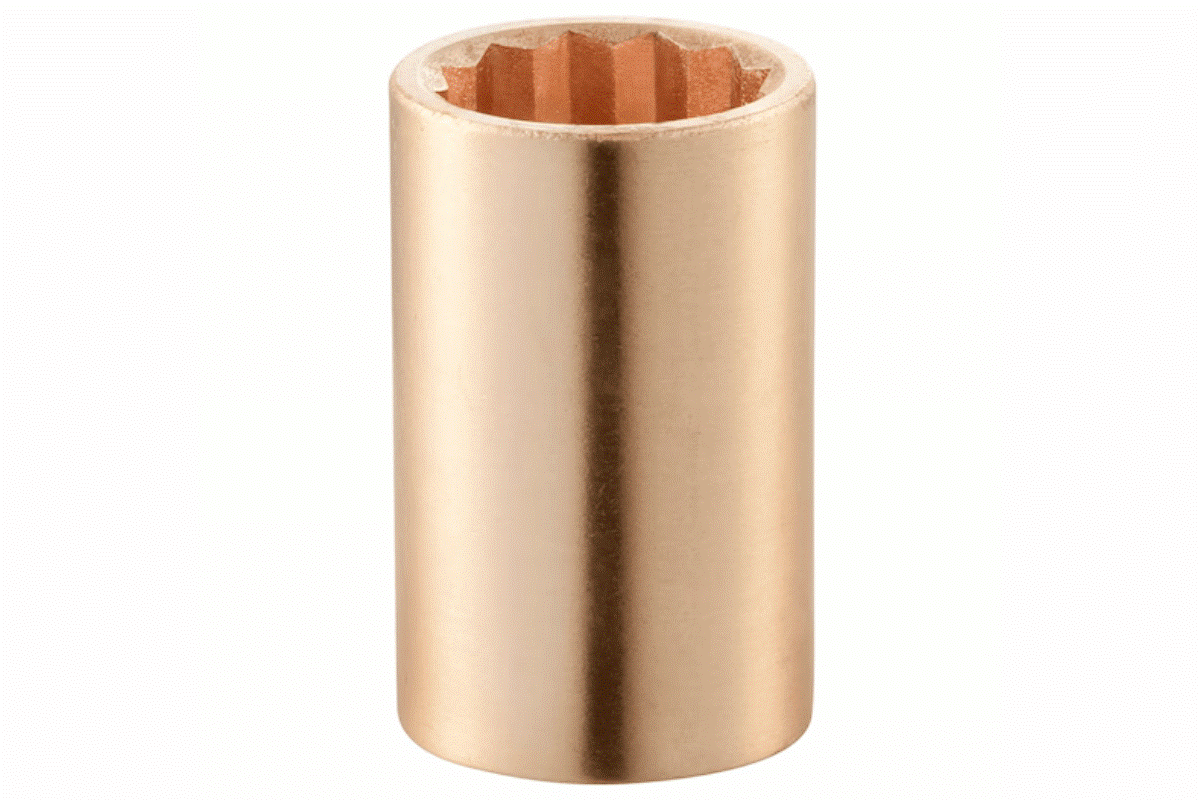

Unlike their steel counterparts, non-sparking tools are made from special alloys that exhibit low-spark generation properties.

Common materials include:

Aluminium Bronze: This alloy offers an excellent balance of strength and spark resistance, making it suitable for various applications across different industries.

Beryllium Copper: The FACOM ADF tool range uses a special Copper-Beryllium alloy with superior mechanical properties compared to other non-sparking alloys. This material is highly spark-resistant, anti-magnetic, and offers excellent corrosion resistance. Its lower density also significantly reduces user fatigue during extended use.

Other Alloys: Copper-nickel and copper-aluminium alloys are also used for specific non-sparking tool applications.

Industries That Require Non-Sparking Tools

If your operation involves flammable materials, you need non sparking tools. Here are the primary industries where these tools are essential:

Oil and Gas: From refineries and drilling rigs to pipeline maintenance, every operation requires non sparking tools to prevent accidental ignition of flammable vapors and gases.

Chemical Industry: Working with volatile chemicals demands absolute safety. Non sparking tools prevent accidental ignition during maintenance, repairs, and routine operations.

Paint and Finishing: In spray booths and areas with paint fumes, standard tools pose serious fire hazards. Non sparking tools minimize this risk significantly.

Grain Handling Facilities: Dust explosions are a significant concern in grain handling operations. Non sparking tools are essential for safe maintenance and daily operations in these environments.

Choosing the Right Non-Sparking Tools

Selecting appropriate non sparking tools depends on several factors:

Material Requirements: Choose the right alloy based on your specific application and tool type.

Application Needs: Ensure the tool’s design and size are suitable for the intended use.

Quality Standards: Ensure your non sparking tools meet industry standards for safety and performance. The FACOM ADF range, available through Sonta Tools, is designed in accordance with widely recognized dimensional standards including ISO and DIN.

Complete Safety Solutions from Sonta Tools

While non sparking tools are crucial, comprehensive safety requires multiple approaches. Sonta Tools offers:

- Insulated Tools: For working with live electrical systems safely

- Customized Tools: Tailored safety solutions designed for your specific requirements

- Expert Guidance: Professional advice on selecting the right safety equipment

Protect Your Workforce Today

Don’t compromise on safety. Investing in quality non sparking tools protects your most valuable assets—your people and your operations.

At Sonta Tools, we partner with top-quality global brands to provide the best safety tools available. Our range includes comprehensive selections of non-sparking tools designed for demanding industrial applications.

Contact Sonta Tools today:

- Call: +971-4-2209942

- Learn more: sontasolutions.com/non-sparking-tools

Your safety is our priority. Choose the right non-sparking tools for your operation and ensure every worker returns home safely.