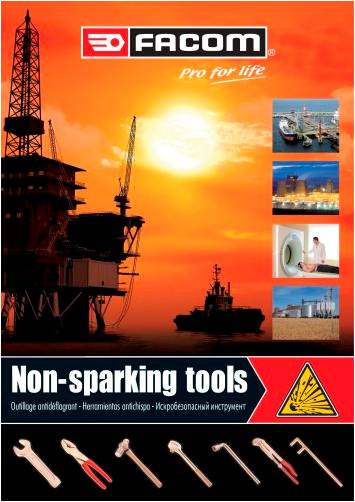

FACOM ADF“ non sparking tools programme

The FACOM ADF tool range has been designed for use in explosive or inflammable atmospheres, where “traditional” steel tools may accidentally create sparks due to friction, impact, or by falling on a hard surface.

The entire FACOM ADF range is made from a special Copper – Beryllium alloy having better mechanical properties than the other alloys proposed for use in non sparking tools.

FACOM has determined the composition of the Cu-Be alloy as well as its specie treatment according to the use of each tool.

In addition to its non sparking properties, the Cu-Be alloy is also anti-magnetic and highly corrosion resistant. Having a lower density, it also signicantly reduces user fatigue. FACOM ADF tools have been designed in accordance with the most widely used dimensional standards (ISO, DIN,…) or adapted to perform the tool’s main functions.